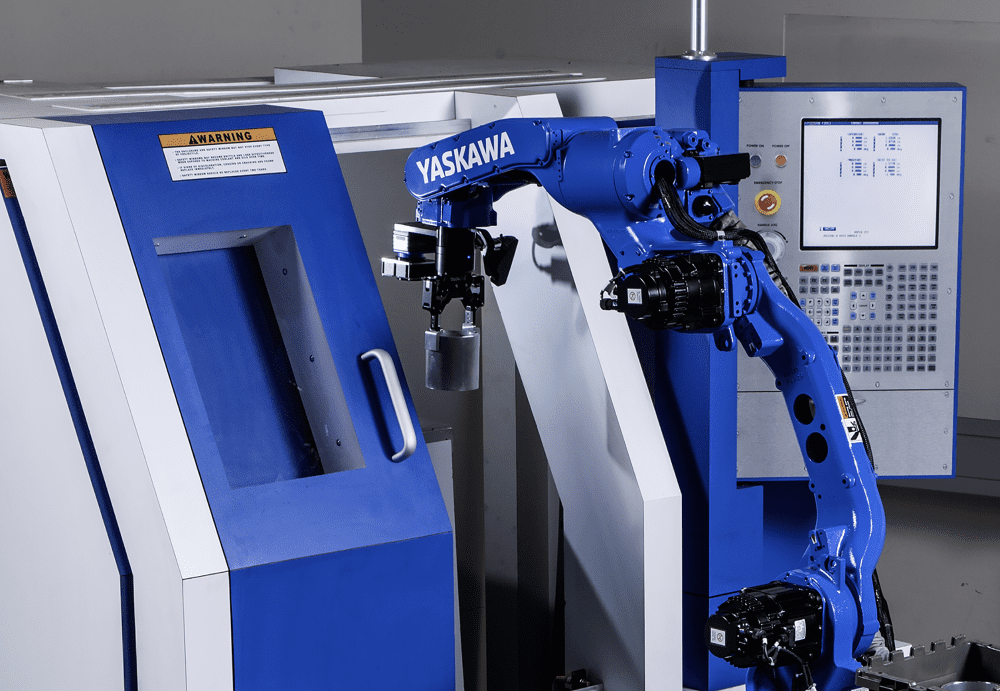

Ever-Roll asked FastLane to help reduce changeover times from part to part. Each employee had their own way of doing things. They did not have a standard way to gather the tools and tooling for each part or a way to make the necessary machine adjustments required to perform the setup for each job. When changing shifts, the employees stepping in to take over a machine, would not understand where the person before them was in the process.

Improving Changeover Process