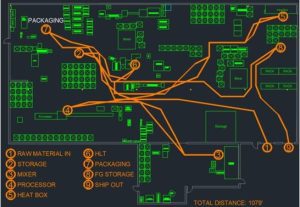

Optimize Your Plant Floor

When a plant is not laid out well, it can cause waste.

Discover How Manufacturers are Revolutionizing Efficiency!

Join us for an insightful session on how manufacturers are optimizing their plant floors and boosting operational efficiency. Don’t miss out on the opportunity to learn about this cutting-edge technology that is transforming the industry!

Presenter

Matt Hoyng

Continuous Improvement Coach

Matt has over 15 years of experience in manufacturing with a proven record of managing site operations focusing on continuous improvement and implementing Lean. He witnessed firsthand the improvements lean manufacturing offers. Now he enjoys sharing this knowledge to help companies succeed by improving their process and culture with Lean methodologies. Matt has a Bachelor of Science in Industrial Technology with a minor in Business from Ohio University and a Lean Six Sigma Green Belt Certification.

Watch our Replays

Watch the Optimize Your Plant Floor Layout Replay:

https://us02web.zoom.us/rec/share/HqS5_X73cUy7kthbyFLUNho_9I8nGR6tR5oAPtaj8P4_mHWOnRxdt3QFFFFZPkXv.04VhMBpdCzB6MB_Z

Passcode: B95BV3S+