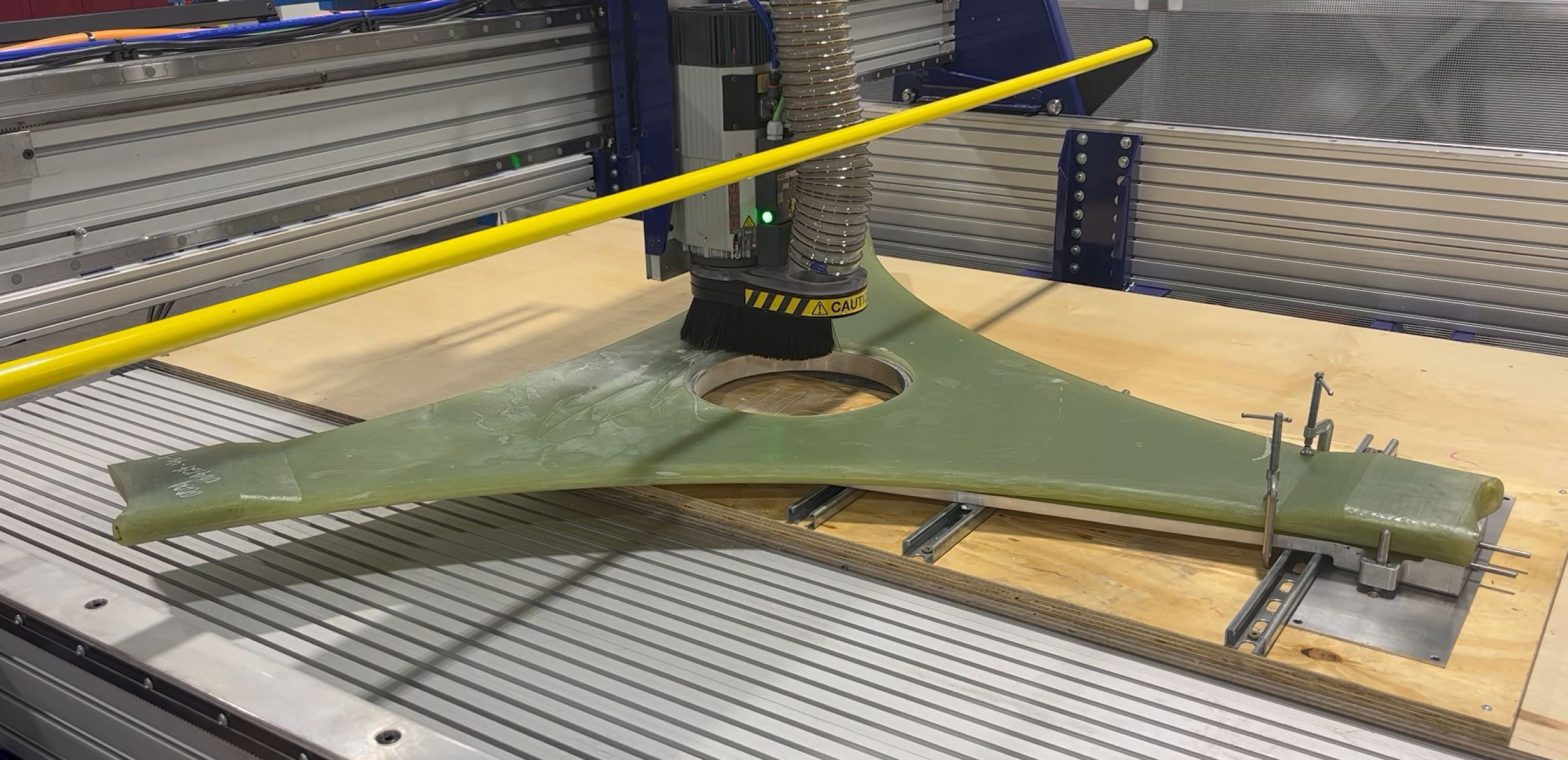

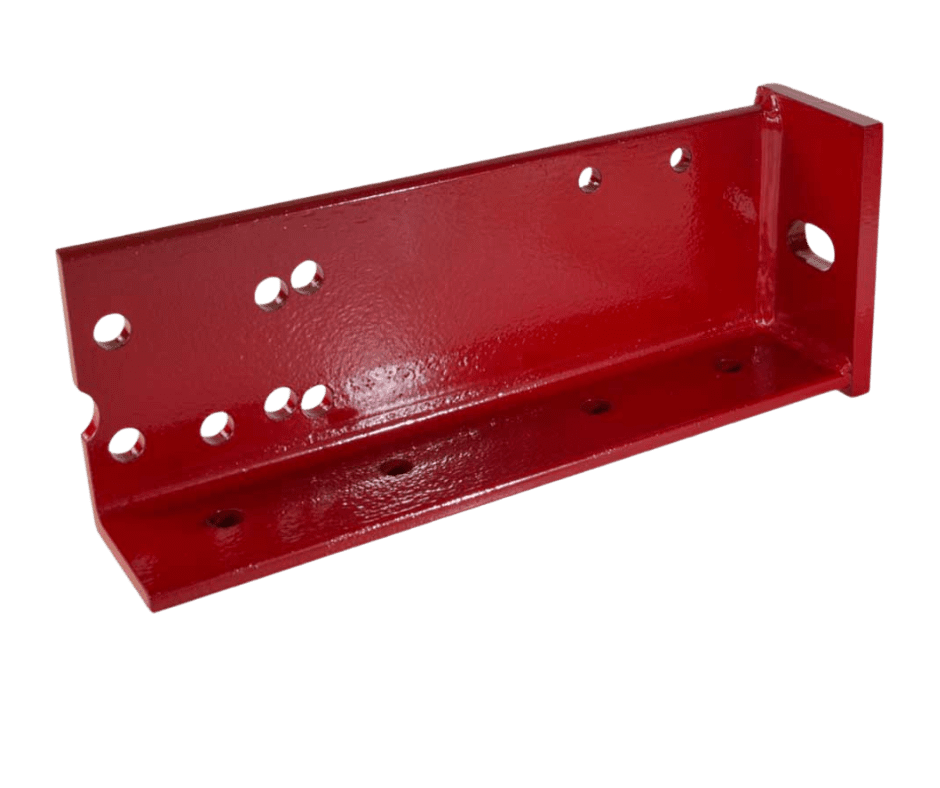

One of Spintech’s key customers needed a product that requires a large amount of detail work. Manufacturing this product includes drilling, cutting, deburring, and trimming. When these activities are done manually, they consume a lot of man-hours.

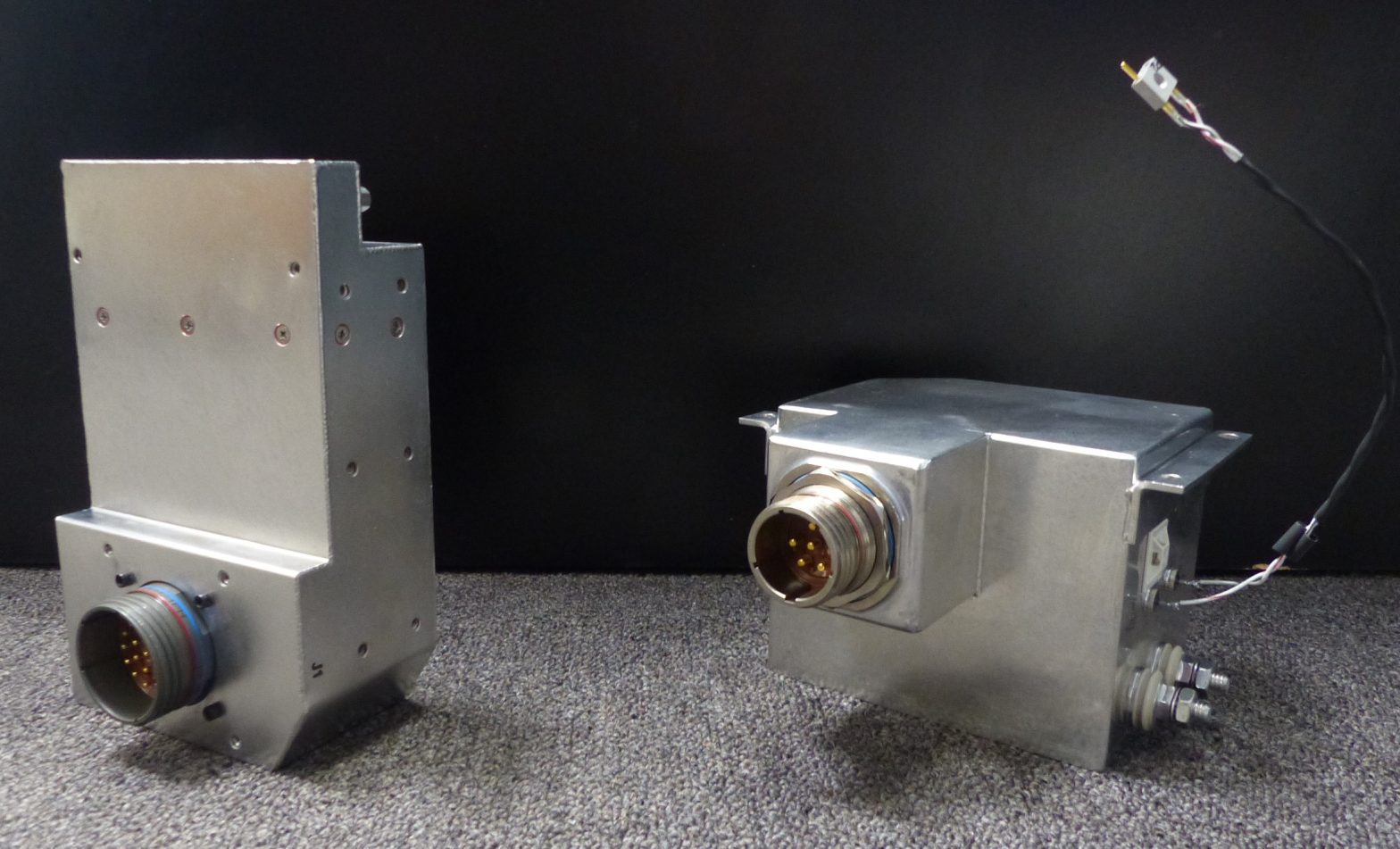

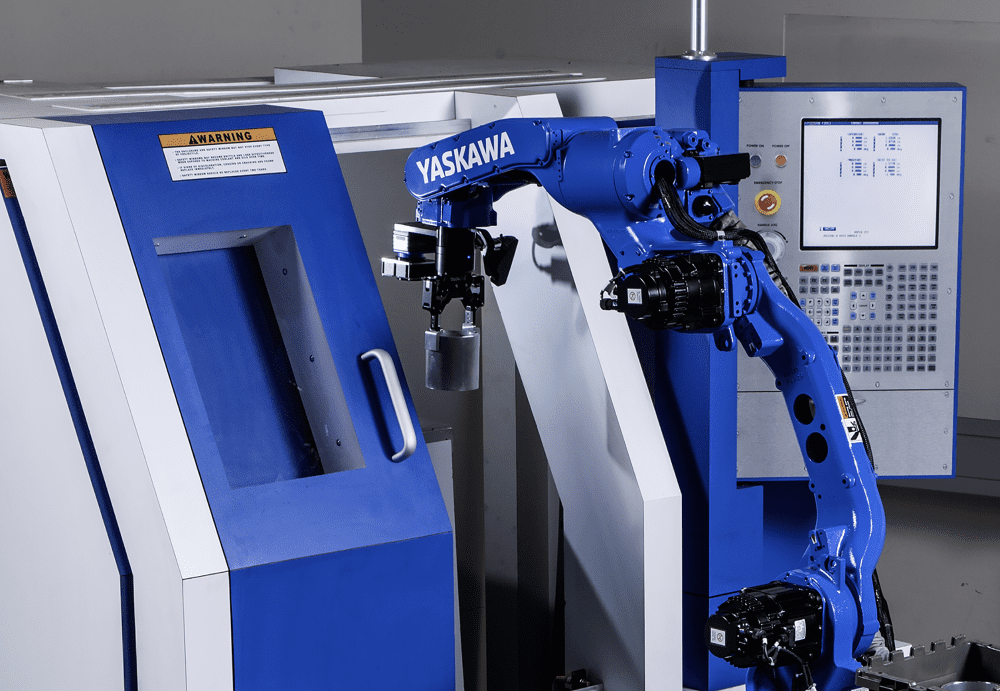

Automation Solutions with Spintech